Ever been inside an organization when someone solves a problem in her area but creates a problem in yours? Systems thinking helps explain how things are connected inside an organization, like processes or the way people are working (or not working) together. Over time, these interactions add up and impact an organization’s ability to execute.

Process re-engineering, six sigma, and associated management interventions all have a common goal: getting people to “look up and around” to really understand, at an organizational level, how their actions impact the entire process, product, service, or impact on the customer. If the organizational culture is not focused on systems-level improvements, trying to do this on your own can often overwhelm people so instead they tune their area, or perhaps collaborate with another area, but aren’t prepared to deal comprehensively with the entire supply chain or processes. True cost or quality gains, however, happen because people are working together to constantly learn, share insights, and take action.

The key, of course, is that everyone shares a common understanding of how things work together, talk with each other to agree on whether something should change, implications for that change, and then agree upon a course of action. Learning how to do this as an organization takes time but there are many examples out there. Toyota is famous for their commitment to kaizen (the continuous improvement across all aspects of your life), and I thought I’d dedicate this blog posting to a tool used within Toyota to help make kaizen a reality.

MIT Sloan’s Managment Review focused on the A3 report, named after the international paper size on which this two page tool is based, to illustrate how a tool can contribute to an entire organization turning into a team of continuous problem solvers. The core of the tool is about story telling to help synthesize lots of information into something easily understood by all. The process of collecting this information and documenting the connections and implications is the key piece to understanding how it impact the entire organization or system.

The A3 tool is just one element of a culture that makes continuous improvements possible. Leadership and technical training, rewards and recognition (promotions, celebrations, etc), and even the stories told to embody the desired behaviours (told by management and the employees) all contribute to a way of participating inside the Toyota organization. Judging by their rapid market share gains they are doing something very right and can be a source of inspiration for leaders in other organizations. Does your organization have a methodology around systems thinking? Is it necessary?

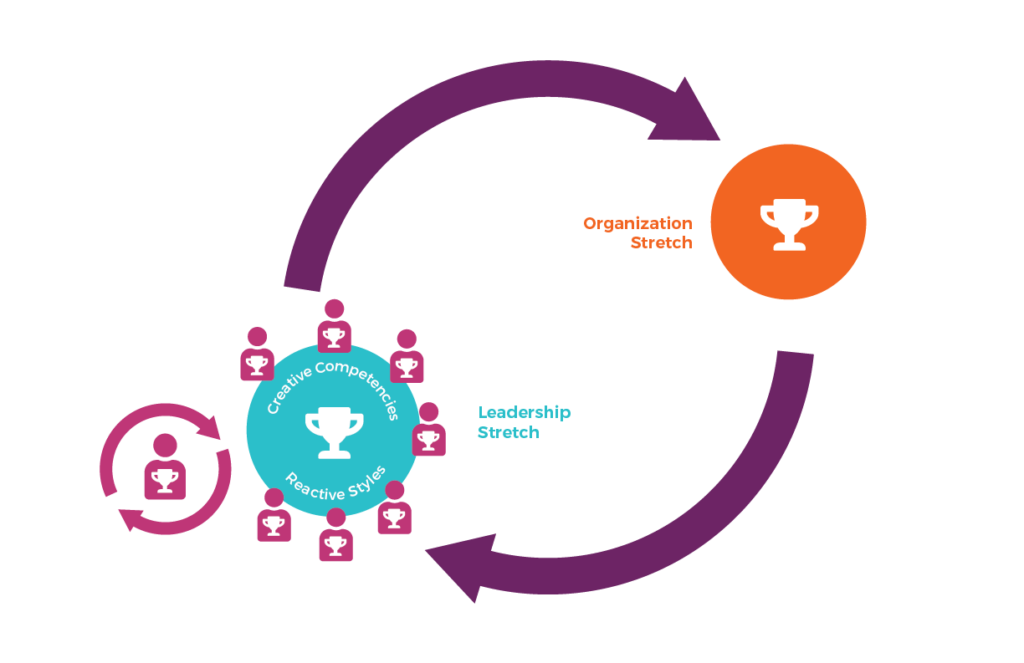

The fantastic thing about leadership, culture, and organizational development is that you can do it in a way that is efficient, laser-focused on the business’ goals and evolution, without a huge cost. At Adaptive Talent we use a very simple tool (shown below) called the three layers of stretch to help people envision the connections between their own development and goals, that of the next “layer” above them such as their team, function, cross-functional groups or processes, and the organization itself. When you engage everyone to reflect how their shared developmental journey and contributions can help everyone achieve desired results and purpose it becomes a very powerful force.

Photo credit and thanks to Juliette Coemelck

—

Adaptive Talent is a talent consultancy designed to help organizations achieve amazing results and ongoing adaptability. Founded in 2008 and based in Vancouver, Canada we offer retained search, assessments, total rewards consulting, training, leadership coaching and development programs, and culture & organizational development consulting.